How Does Carbon Brush Operate

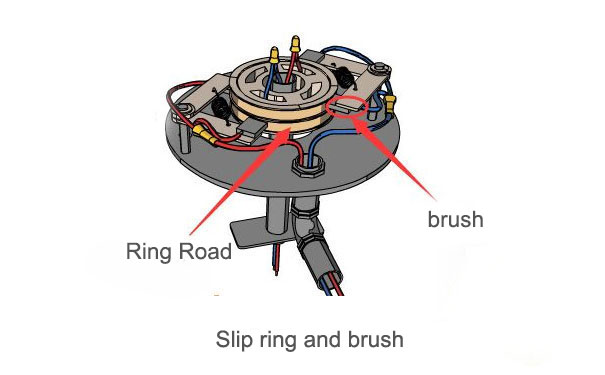

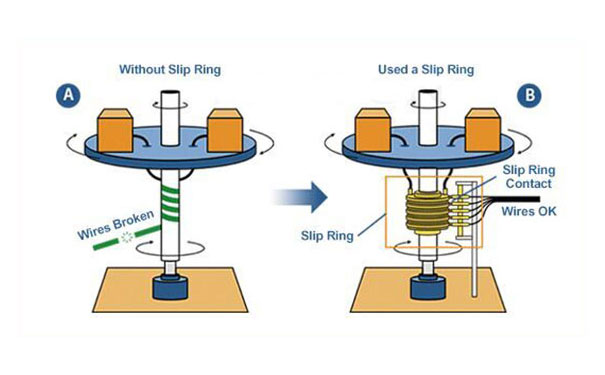

The carbon brushes is certainly one of the important components of the slip ring, which is certainly given less importance as compared to the other. On the flip side, it is the most important part of any slip ring. The carbon brushes are commonly referred to as the rotor brush. They are considered to be of a smaller size in general. It acts as a medium that conducts and transfers electrical current from the stator wires to the rotational wires. It is mostly used in generators and motors. One or more carbon blocks are used to make carbon brushes, and they are available in one more terminal.

In general, there are more than one carbon brushes in the motors or generators. The slip ring suppliers have categorized carbon brushes which are used in slip rings into different categories depending on the kind of equipment in which the slip ring will be used.

There are three operational parameters which come along in the use of carbon brush

Mechanical

In most cases, the rotating shaft gets attached with the slip ring or most commonly as a commutator, The slip ring brushes are pushed into the commutator to establish and maintain the contact using a spring. Another key point here to note is that the slip ring surface should either not be too glossy or rough, in order establish a proper contact between the slip rings and brushes which in turn adds to the performance level of the device.

Electrical

The contact brushes come into play for transferring the current form the rotating shaft to other important parts of the slip ring. There is something called contact spots between a brush and the slip rings, these are basically minute spaces in the bushes, which in turn makes the contact between the slip ring and brush more fruitful. The contact spaces should be evenly spread evenly spread in the brush in order to ensure smooth operation and zero excess load which in the long run might hamper the functioning of the slip ring. If the contact spots are not evenly spread out, then there are chances that slip ring surface might be irreversibly damaged, so the aforesaid inefficiency of slip ring becomes natural.

Various slip ring manufacturers support the use of high resistivity carbon brushes. The idea behind the use of such carbon brushes is that it prevents electrical arc between the slip and the brush interface.

In aces of DC motors, it is highly recommended to establish an apt power density for the motors to operate at their best. Further, adequate analysis and calculation of power density is necessary to be ascertained. Also, in the case of alteration of application, the brush density should also be altered accordingly.

Physical and chemical

The physical and chemical parameter falls on the line of external factor affecting the carbon brushes and quite minimally on the brush itself. Having said that, the external factors can have a huge influence on the functioning of the carbon brush.

For an instance, the humidity level in the air should be present at a certain scale for the contact between the slip ring and the brush to established properly. In case of dry atmospheric conditions normal brush won’t operate properly, in such cases special type of brushes are used. Further, dust hydrocarbon and oil can adversely affect the functioning of the carbon brushes, so such elements should be kept away from the brushes.

Others:

Pri: The Various Types Of Slip Rings Next Slip Ring Applications and Types

Others:

Advantage Of A High-frequency Slip Ring

An Insight into HD Slip Ring and Virtual Reality Technology

High-frequency Slip Ring - The Ideal Modern Slip Ring

The Design Cue of Turbine Slip Rings And Its Advantages

Introduction to Slip Rings Used in Medical Field

Slip Rings In Wound Rotor Induction Motor

Rotary Electrical Connector Solving Slip Ring Dilemma for Data Equipment Manufacturer

How Does Slip Ring Induction Motor Start?

The Interdependence of Slip Ring and Thermocouple

Assembly and Application Of Mercury Slip Ring