Getting Familiarized With Different Aspects of Slip Rings

What are slip rings after all?

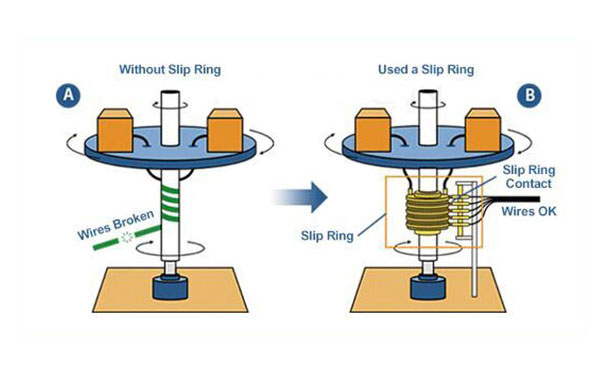

Keeping it simple, the slip ring is a type of electromechanical device, which is used to transmits electrical signals and power from the stationary component to the rotating component. They can be applied to any kind of electromechanical device, which has a requirement of a continuous flow of power and signal from the stationary structure to the rotating structure. It helps in simplifying the operational process and at the same the prevents damage prone wire from getting dangled in the movable joints.

How do they work?

The function of slip rings is based on the idea of making an electrical connection between the stationary and rotating part, so as to allow continuous flow of power and signal. Now the question arises as to how actually this transfer takes place? When the electrical or data signal is generated, they are transferred by the sling ring using contact between the conductive ring and carbon brushes. The contact medium may differ depending on the kind of slip ring being employed in the system, but largely it is the contact medium, which makes the flow possible through the slip ring unit, before finally being transferred to the rotating structure.

Transmitting signals with help of slip ring

Now, the slip rings are not just about transmitting power there is a different kind of slip ring which is designed, especially, for transferring the high-frequency data signals and they are commonly known as ethernet slip ring. The circuits of such kind of slip rings are made of sliding contact. In some slip rings which are used for transmitting signal minimum, two brush contacts are preferred. They are also made up of some of the precious metal which helps immensely in improving the quality of signals transmitted. It also helps in minimising the loss of signals through contact resistance.

Slip ring maintenance

The use of the slip ring is to make the operational process simpler and cost-effective. But things can backfire at times if the slip rings are maintained properly. The lack of proper maintenance may leave the slip ring unit to be ineffective and to counter the downside of lack of maintenance has to covered with the addition of new components and sometimes the entire unit has to be replaced, so it no longer mains a cost-effective method, instead takes additional cost to get things in order.

Some of the flaws regarding maintenance which needs to be avoided are mentioned below.

1.Improper scheduling of maintenance, which is the most common flaw made the users.

2.Going through the maintenance process without actually worrying about the methods employed for maintenance, which is crucial for increasing the lifespan of the slip ring.

3.One of the other mistakes which the user make stems from the choice of the slip ring, without actually working out about the slip ring design that suits the concerned device.

The bottom line here is that slip rings are useful and they prove to be highly beneficial in terms of output. But at the same time, proper maintenance schedule is necessary in keeping the order of advantages straight and not letting the addition of slip ring become a burden of any sort.

Others:

Pri: Maximizing Slip Ring Lifecycle And Performance Next Application of Induction Motor Slip Rings

Others:

Advantage Of A High-frequency Slip Ring

An Insight into HD Slip Ring and Virtual Reality Technology

High-frequency Slip Ring - The Ideal Modern Slip Ring

The Design Cue of Turbine Slip Rings And Its Advantages

Introduction to Slip Rings Used in Medical Field

Slip Rings In Wound Rotor Induction Motor

Rotary Electrical Connector Solving Slip Ring Dilemma for Data Equipment Manufacturer

How Does Slip Ring Induction Motor Start?

The Interdependence of Slip Ring and Thermocouple

Assembly and Application Of Mercury Slip Ring