The Various Types Of Slip Rings

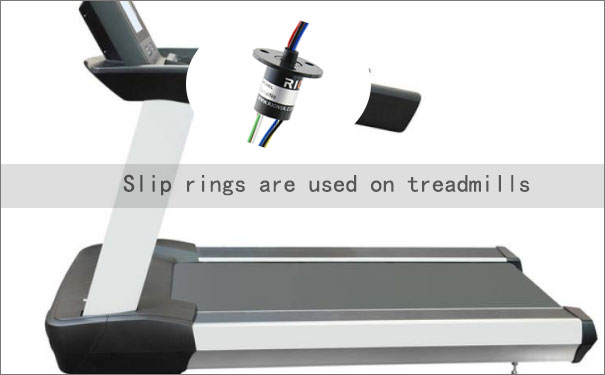

We have heard time and again about what a slip ring is and how they are used in various electronic components. They are primarily used to transfer electric power and signal to one component of an electronic device to another.

A rotary slip ring is that part of an electrical appliance that helps in transferring the power or signal from a stator part to a rotator part. Generally, any wired connection cannot make the transfer of power possible so easily. Hence, adding a slip ring makes this process possible with the help of brushes which stay in constant touch with the part that required the energy.

Different slip ring assemblies

A slip ring assembly has fully integrated components like the bearing and housing. The sizes and shapes depend largely on the specifications provided by the customers. These are available in either silver or gold contacts and these units are responsible for carrying the signal and power in a variety.

The channels via which the power is carried vary between one and many hundreds and are directly proportionate to the application, that is, the more complex the device, the more number of variations.

What are high-speed units?

Just like the name suggests, these high-speed units are specially designed to be used in high-speed applications and are often air or liquid cooled and may have a brush lifting mechanism that can counter the rapid wear and tear of the brush.

These components are used in various testing applications and are so designed to offer very less noise property of the electricals. They are available in either gold or silver contacts and can carry a wide variety of data signal channels.

Miniature slip rings

The miniature slip rings or compact slip rings are used in electric motors and channels that are used in places where there is a space crunch. In limited space condition, like in missile guideline systems and in aircraft instruments, these small mechanisms are put in. However, despite their size, they can still pull off high specification like good operating speed and lifespan along with low electrical noise level.

These miniature slip rings are available in only gold contact. However, their size is directly proportionate to the number of channels that are required. As for an example, an 18-channel slip ring would be around 12 mm long and 5 mm in diameter.

Twist capsule

Rotating contacts have a simpler solution when there are limited rotations available. This solution is the twist capsule, which allows the continuous movement of turning without the wiring looms. These applications are used in many simpler applications like the sighting equipment, cameras and pitch controls.

Slip rings have becomes an integral part of most of the devices and appliances. Such is their importance that the industry is readily looking to upgrade the technology with every passing day to make things better for the consumers and also for the benefits of the device itself. Also, the natural wear and tear are a lot lesser with the recent advancements in the development.

Others:

Pri: Next How Does Carbon Brush Operate

Others:

Advantage Of A High-frequency Slip Ring

An Insight into HD Slip Ring and Virtual Reality Technology

High-frequency Slip Ring - The Ideal Modern Slip Ring

The Design Cue of Turbine Slip Rings And Its Advantages

Introduction to Slip Rings Used in Medical Field

Slip Rings In Wound Rotor Induction Motor

Rotary Electrical Connector Solving Slip Ring Dilemma for Data Equipment Manufacturer

How Does Slip Ring Induction Motor Start?

The Interdependence of Slip Ring and Thermocouple

Assembly and Application Of Mercury Slip Ring