How Are Split Rings Different From Conventional Slip Rings?

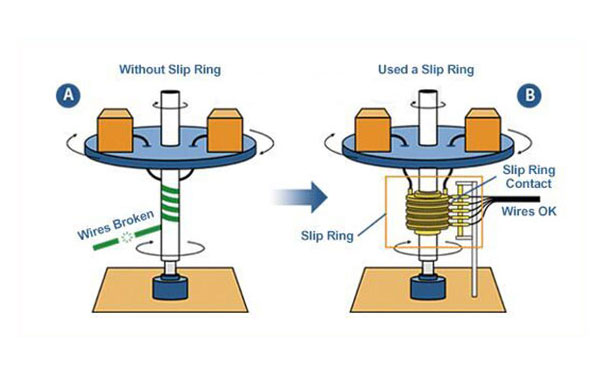

Slip rings are electromechanical devices that allow the transmission of electrical signals and the power from a stationary structure to a spinning structure. It are used in any of the electromechanical systems that require a continuous, unrestrained and intermittent rotation, at the same time transmitting data signals. It is used to improve the mechanical performance, to simplify the system operations and to remove the wires prone to damage that hang from the movable joints.

It has become an essential part of many appliances and electrical equipment. Almost, all these types of equipment depend extensively on the slip ring rotor or the wound rotor. A motor slip ring is a type of slip ring in which rotor windings are attached through the rings to the external resistance. Adjustment of resistance allows the control over the torque characteristic of the slip ring motor. There are, however, a lot of difference between a slip ring and the one used as an alternative, the split ring.

A split ring can be used as commutators that reverse the direction of the current flow through a coil, after each half rotation of that coil. Because of this, the coil keeps spinning in one direction. It is known as a split ring because of the fact that it is a copper-made component which is split in two parts from the center. There is a brush which is used to attach the outer diameter of a split ring. For a DC generator, the current of AC is generated which then transforms into DC before collections.

Difference between the slip ring and split ring can be explained by the following points

1. A rotary slip ring is used for transfer the power and data signals from a stationary structure to a rotating structure of an AC machine. A split ring, on the other hand, is used to reverse the direction of flow of the current.

2. A slip ring can be termed as the continuous part of an electronic device. The split ring on the other side is not a continuous part as it is split into two parts or more.

3. A slip ring can be used to supply power to an AC motor from an AC generator while the split ring is used to provide pulsating voltage to a DC motor. This difference also explains the fact that slip rings are used in AC motor while the split ring finds its place in a DC motor.

4. A slip ring collects power from a DC generator with the help of the static devices known as brushes, which then passes the power current to slip rings. These when connects to the motor coils, the power transmits from a static to a rotary part of the elements. The split ring, however, is used to change the polarity of the current.

Both the slip ring and the split ring are constructed from a metal called copper, but they differ in designs. The slip ring is a circular ring while a split ring comes with an air gap in between the split parts.

Others:

Pri: Purpose Of Using Slip Ring In An Alternator Next The Key Elements Of The Slip Ring Selection Process

Others:

Advantage Of A High-frequency Slip Ring

An Insight into HD Slip Ring and Virtual Reality Technology

High-frequency Slip Ring - The Ideal Modern Slip Ring

The Design Cue of Turbine Slip Rings And Its Advantages

Introduction to Slip Rings Used in Medical Field

Slip Rings In Wound Rotor Induction Motor

Rotary Electrical Connector Solving Slip Ring Dilemma for Data Equipment Manufacturer

How Does Slip Ring Induction Motor Start?

The Interdependence of Slip Ring and Thermocouple

Assembly and Application Of Mercury Slip Ring